In recent years, the logistics industry has witnessed explosive growth, with warehouses and fulfillment centers becoming more complex and demanding. One of the key advancements driving this transformation is the rise of autonomous robots, particularly “goods-to-person” robots, which are reshaping how products are moved within warehouses. Among these innovations, CPJROBOT’s autonomous follow robots stand out as a game-changer, offering advanced solutions for efficiency, cost reduction, and safety.

In this blog, we’ll dive into how CPJROBOT’s intelligent follow robots are transforming logistics operations, the challenges posed by traditional human labor in these environments, and why autonomous robots are the future of logistics.

The Growing Need for Automation in Logistics

The logistics sector has experienced an unprecedented boom, driven by the rise of e-commerce and consumer demand for faster deliveries. According to recent reports, warehouse automation has become a priority for companies looking to stay competitive. Manual labor in warehouses, once a common sight, is now under pressure due to several factors, including:

- Labor shortages: Many logistics companies are struggling to hire enough workers to meet growing demands.

- Safety concerns: Manual labor in busy warehouses can lead to workplace accidents and injuries.

- Inefficiency: Traditional workflows often involve human workers manually transporting goods across the warehouse, which is both time-consuming and costly.

To address these issues, more companies are turning to autonomous robots like CPJROBOT’s follow robots to streamline their operations and enhance productivity.

CPJROBOT’s Autonomous Follow Robots: Key Features and Technology

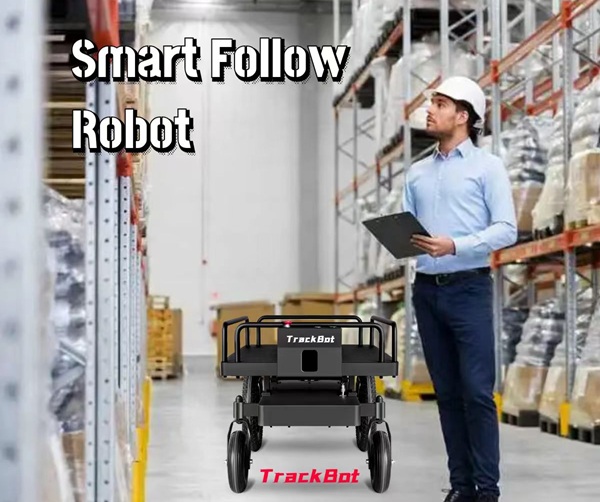

CPJROBOT’s autonomous follow robots are designed to revolutionize the way goods are transported within logistics centers. By utilizing a combination of AI-driven perception, advanced motion planning, and LiDAR technology, these robots offer unparalleled efficiency and flexibility in handling warehouse tasks.

Here’s how CPJROBOT’s robots stand out in the logistics sector:

1. Autonomous Navigation and Path Planning

CPJROBOT’s follow robots use autonomous perception to recognize and understand their surroundings in real-time. These robots are equipped with LiDAR sensors that allow them to detect obstacles, such as other robots, workers, or equipment, and autonomously navigate around them.

Once they receive their mission—such as delivering packages from one location to another—the robots use intelligent motion planning algorithms to determine the most efficient route, avoiding obstacles and choosing the quickest path. This level of autonomy ensures that robots can work independently, without requiring constant oversight from human operators.

2. Heavy Load Capacity and Extended Range

Unlike drones, which are limited by their payload capacity and range, CPJROBOT’s follow robots are built for larger tasks. These robots can carry anywhere between 10 to 20 packages at a time, depending on the specific model, which significantly increases throughput compared to traditional methods.

Additionally, the robots offer high endurance in terms of battery life, making them perfect for long shifts within large warehouse environments. This is a stark contrast to drones, which typically have shorter flight durations and are less efficient for ground-based deliveries.

3. Cost-Effective and Environmentally Friendly

One of the key advantages of CPJROBOT’s autonomous follow robots is their low operating costs. While employing human workers to manually transport packages can be costly, robots offer a far more cost-effective solution. The robots use electric drives, making them not only energy-efficient but also environmentally friendly, emitting zero pollutants during their operation.

This can translate into significant savings in terms of both labor and environmental impact, making them an ideal solution for businesses looking to cut operational costs while adhering to sustainability goals.

The Limitations of Human Labor in Logistics

While human workers have traditionally been the backbone of warehouse operations, the increasing complexity and scale of logistics centers have exposed several weaknesses in relying solely on manual labor. Let’s explore the limitations of human workers and how autonomous robots like CPJROBOT address these challenges:

1. Labor Shortages

As e-commerce continues to grow, so does the demand for workers in warehouses. However, finding skilled labor for these positions is becoming more difficult, especially with the rise of remote work and the ongoing impacts of global events like the COVID-19 pandemic. Many logistics companies are finding it hard to hire and retain workers, leading to delays and increased costs.

By deploying autonomous follow robots, warehouses can reduce their reliance on human labor for repetitive and physically demanding tasks, allowing businesses to operate with fewer human workers while maintaining high productivity.

2. Injuries and Safety Concerns

Warehouse environments are often hazardous, with heavy lifting, fast-moving equipment, and tight spaces posing risks to workers. According to OSHA (Occupational Safety and Health Administration), warehousing jobs are among the most dangerous, with high rates of injury. Human workers are more prone to accidents like slips, trips, and falls, which can cause serious injuries.

CPJROBOT’s follow robots mitigate these risks by performing tasks that are physically demanding and potentially dangerous. The robots can work around the clock, minimizing the risk of injury and improving safety within the warehouse.

3. Inefficiency and High Labor Costs

Manual labor is inherently less efficient than automation. Workers have to take breaks, deal with distractions, and may have varying levels of productivity throughout the day. This leads to slower processing times and a higher likelihood of errors.

With CPJROBOT’s autonomous robots, the speed and efficiency of warehouse operations are significantly improved. These robots work 24/7, follow pre-determined paths with precision, and avoid bottlenecks, leading to faster and more accurate deliveries. Moreover, the cost of operating these robots is much lower compared to maintaining a large workforce.

The Future of Logistics is Autonomous

As the logistics industry continues to evolve, the integration of autonomous robots like CPJROBOT’s follow robots is set to become a standard. These robots offer a wide range of benefits—from enhanced efficiency and reduced labor costs to improved safety and environmental sustainability. With their advanced sensors, AI-driven algorithms, and heavy load capacity, CPJROBOT’s robots are well-equipped to handle the growing demands of modern logistics operations.

Are you ready to take your logistics operations to the next level? CPJROBOT specializes in LiDAR and intelligent robotics designed for seamless automation. Reach out to us today to learn more about how our advanced solutions can improve your warehouse efficiency and help you stay ahead in the competitive logistics landscape.